Tribology is the science and engineering of interacting surfaces under load and shear. It includes the study of adhesion, friction, lubrication, and wear. In the last decades, tribology has become a highly interdisciplinary field, which attracts attention from physicists, chemists, engineers, materials scientists, and biologists.

The renewed interest in tribology has been fueled by several factors, among which the advent of new experimental and computational techniques that opened the way to for fundamental studies on the origin of friction, and an increased attention to the enormous adverse effects of friction on global energy loss and the environment.

We apply computational methods to both investigate fundamental mechanisms in tribology and design materials to reduce friction.

Fundamental understanding on frictional phenomena

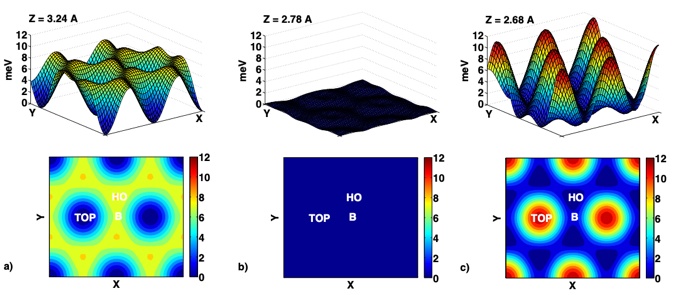

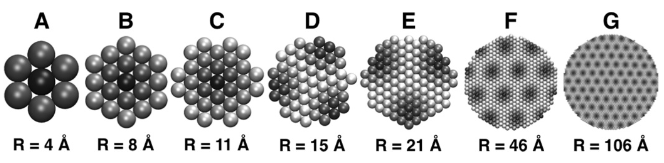

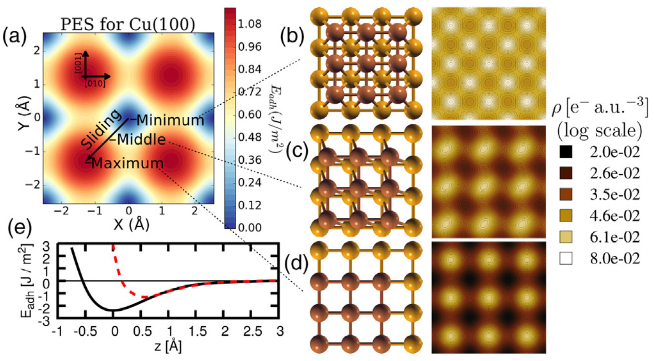

Relevant information on the adhesion and resistance of sliding of an interface can be obtained by the analysis of the potential energy surface (PES) that describes the surface adhesion during sliding [12, 22, 27]. For example, we predicted a pressure-induced friction collapse in systems with an anticorrugating PES [14]. And identified the collective atomistic mechanisms that trig the onset of frictional slip, which we described as a nucleation process [19]. We also showed that shrinking the size of a body in contact with a substrate increases its commensurability and resistance to sliding [40].

We unraveled the fundamental nature of adhesive and friction forces by correlating them with the electronic charge displacements at the interface of two mating surfaces [50].

Thanks to the pioneering application of ab initio molecular dynamics to simulate sliding interfaces we “observed” stress-induced reactions and the tribo-catalytic conversion of molecules in thin films [29, 59, 88, 99]

Lubricant materials and tribochemistry

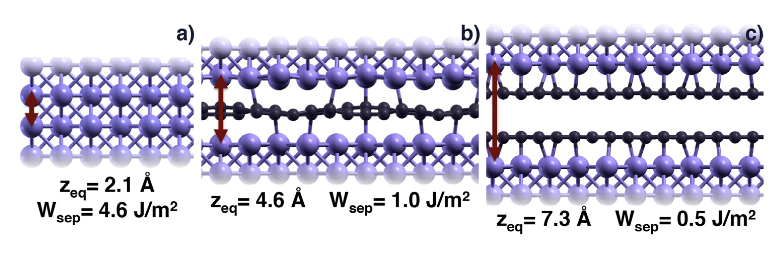

The function of many lubricant materials is to reduce interfacial adhesion. This is achieved in either by covering the surfaces by inert layers such as MoS2 and coatings, as diamond or DLC, or by forming slippery “tribofilms” are formed in situ through tribochechemical reactions, i. e. reactions assisted by mechanical stresses, involving lubricant additives.

We applied quantum mechanical and machine learning simulations to unravel the lubrication mechanism of:

- 2D materials, such as graphene [26, 27, 33, 39, 42, 56, 76], MoS2 and other TMD [30, 33, 42, 43, 66, 88], Phosphorene [57, 77, 83, 97, 103], MXenes [74, 81, 93, 95, 104];

- carbon coatings, such as diamond and DLC [17, 22, 24, 29, 36,46, 75, 78, 89, 91, 94, 106];

- lubricant additives used in oils, such as organophosphorus complexes [45, 47, 48], MoDTC [54, 61, 66, 68, 73], ZDDP [72, 74, 90, 110] and, more environmental friendly additives for water-based lubricants [79, 98, 99, 100, 107].

The cited references are visible here.